Starting off with How to Save Thousands with Preventive Fleet Care, this introduction aims to provide a captivating glimpse into the topic, enticing readers to delve deeper into the cost-saving strategies and benefits discussed within.

The following paragraph will delve into the specifics of preventive fleet care and how it can lead to significant financial savings for fleet owners.

Understanding Preventive Fleet Care

Preventive fleet care involves regularly scheduled maintenance tasks and inspections carried out on a fleet of vehicles to ensure optimal performance and longevity.

Implementing preventive maintenance for fleets offers several benefits, including:

- Increased lifespan of vehicles

- Reduced risk of unexpected breakdowns

- Improved safety for drivers and passengers

- Cost savings on major repairs

Common Preventive Maintenance Tasks for Vehicles

Some examples of common preventive maintenance tasks for vehicles in a fleet include:

- Regular oil changes to keep the engine running smoothly

- Checking and replacing air filters to maintain air quality and engine efficiency

- Inspecting and rotating tires to ensure even wear and optimal traction

- Testing the battery and replacing it when necessary to avoid breakdowns

- Checking and topping up fluids such as brake fluid, coolant, and transmission fluid

Cost-Effective Practices for Preventive Fleet Care

Regular maintenance is crucial for keeping your fleet running smoothly and avoiding costly breakdowns. By implementing cost-effective practices for preventive fleet care, you can save thousands of dollars in the long run. Here are some strategies to help you maximize cost savings:

Regular Inspections

One of the most cost-effective maintenance strategies for fleets is to conduct regular inspections. By identifying and addressing issues early on, you can prevent small problems from turning into major repairs that can drain your budget. Inspections allow you to catch potential issues before they escalate, saving you money on expensive repairs down the line.

Proactive Maintenance Scheduling

Another tip for cost-effective preventive fleet care is to schedule maintenance proactively. Instead of waiting for something to break down, create a maintenance schedule that includes regular check-ups and tune-ups. By staying ahead of potential problems, you can avoid costly emergency repairs and keep your fleet running smoothly.

Use of Technology

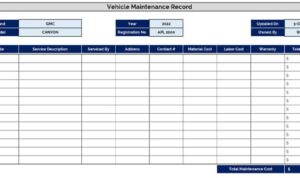

Utilizing fleet management software can also help you save money on maintenance costs. These tools can help you track vehicle performance, schedule maintenance tasks, and identify areas for improvement. By using technology to optimize your maintenance processes, you can reduce downtime, increase efficiency, and ultimately save money in the long run.

Importance of Regular Inspections

Regular inspections play a crucial role in preventing costly repairs for fleet vehicles. By conducting routine checks and maintenance, fleet managers can identify potential issues early on, saving money in the long run.

Early Detection of Issues

- Regular inspections allow for the early detection of mechanical problems such as worn-out parts, leaks, or faulty components.

- Addressing these issues promptly can prevent them from escalating into major repairs that are more expensive to fix.

- By catching problems early, fleet managers can avoid unexpected breakdowns that can lead to costly downtime and lost productivity.

Neglecting Regular Inspections

- Failure to conduct regular inspections can result in undetected issues that worsen over time, leading to more extensive and expensive repairs.

- Neglecting maintenance can also reduce the lifespan of fleet vehicles, resulting in the need for premature replacements that are costly.

- Without regular inspections, fleet managers may miss out on the opportunity to identify and address potential problems before they become major issues.

Extending Vehicle Lifespan through Preventive Care

Preventive fleet care plays a crucial role in extending the lifespan of vehicles, ultimately leading to significant financial benefits for businesses. By implementing regular maintenance routines and addressing issues promptly, companies can ensure that their fleet remains in optimal condition for a longer period of time.

Examples of Preventive Maintenance Tasks

- Regular oil changes: Changing the oil at recommended intervals helps to lubricate the engine, reduce friction, and prevent wear and tear.

- Tire rotation and alignment: Ensuring that tires are rotated and aligned properly can extend the lifespan of tires, improve fuel efficiency, and enhance overall vehicle performance.

- Brake inspections: Regular brake inspections help to identify and address any issues early on, preventing major brake system failures and ensuring the safety of drivers and passengers.

- Fluid checks: Regularly checking and topping up fluids such as coolant, transmission fluid, and brake fluid can prevent overheating, improve performance, and prolong the lifespan of various vehicle components.

- Filter replacements: Replacing air filters, oil filters, and fuel filters as recommended can improve engine efficiency, reduce emissions, and prevent damage to engine parts.

Conclusive Thoughts

In conclusion, understanding the importance of preventive fleet care and implementing cost-effective maintenance practices can not only save thousands but also prolong the lifespan of vehicles. By prioritizing regular inspections and timely maintenance, fleet owners can ensure optimal performance and minimize repair costs in the long run.

FAQ Resource

How often should preventive maintenance be conducted?

Regular preventive maintenance should be scheduled based on the manufacturer’s recommendations and the specific needs of the fleet, typically every few months or after a certain mileage threshold.

What are some cost-effective strategies for fleet maintenance?

Cost-effective strategies include timely inspections, proactive maintenance scheduling, investing in quality parts, and training staff to perform basic maintenance tasks.

Why is early detection during inspections crucial for cost savings?

Early detection allows fleet owners to address minor issues before they escalate into costly repairs, saving both time and money in the long term.

Can neglecting regular inspections impact fleet maintenance costs?

Yes, neglecting regular inspections can lead to undetected issues worsening over time, resulting in higher repair costs and potentially shorter vehicle lifespans.